Advantages

Increasing Process Efficiency in Areas Like In-house and Field Service

Data

Master, Movement, and Status Data (Hot + Cold Data) for over 150,000 TRUMPF Products

Solution

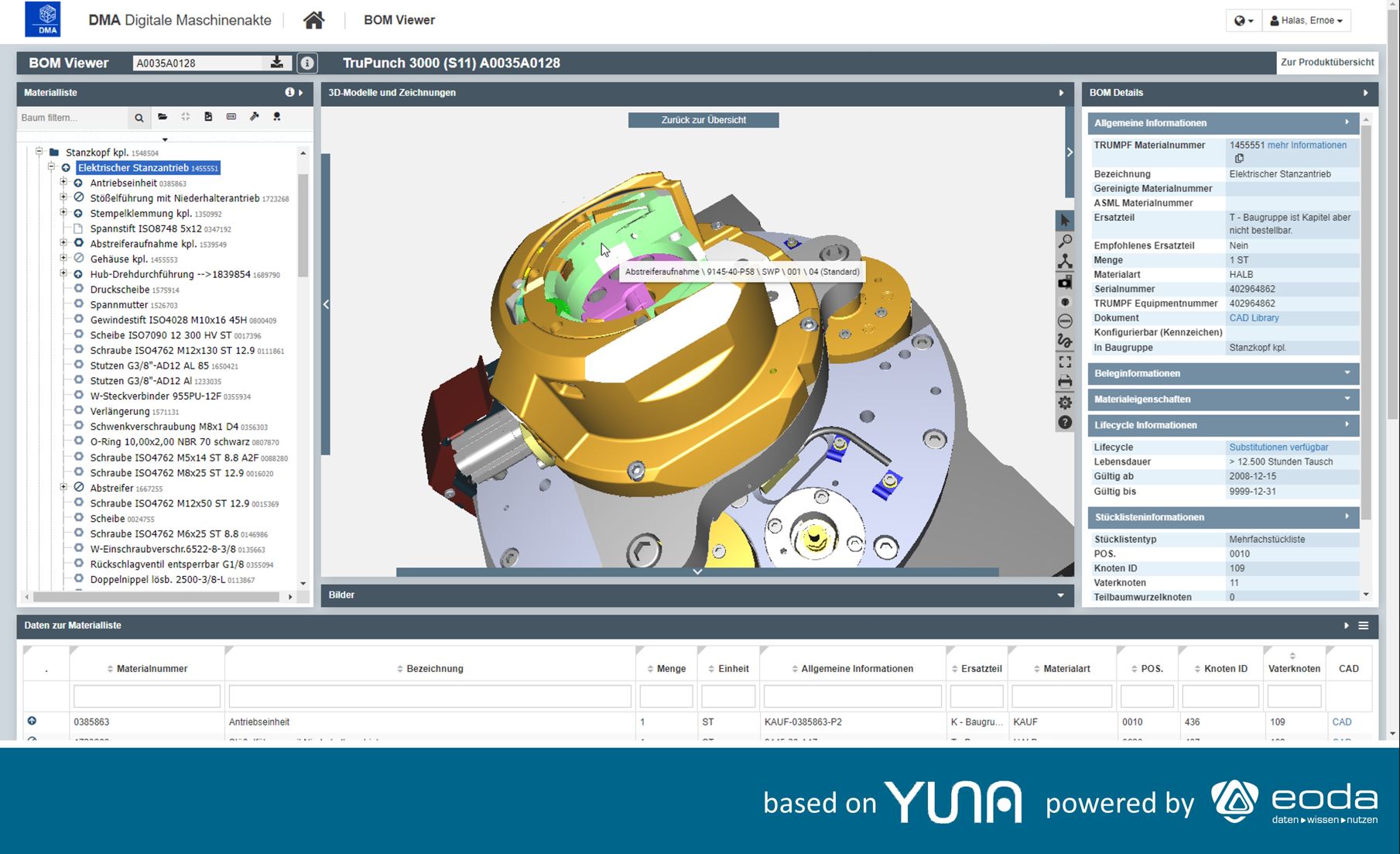

Digital Machine File as a "Single Point of Truth" for Spare Part and Condition Research Based on a Self-Developed Analytics Platform

Challenge

TRUMPF is dedicated to advancing production technology and digital networking, making it even more economical, precise, and future-proof. The company aims to optimize manufacturing and its upstream and downstream processes, as well as internal workflows. The Digital Twin holds significant potential here. As is often the case, the challenges lie within the data foundation and target audience-specific visualization.

Goal

The following goals were pursued in the first of several project phases during the establishment of the Digital Twin:

- Content-driven establishment of a data integration platform (data basis)

- Interfaces to process-leading core and non-core systems

- Scalable interfaces to supply data to additional systems

- Logic within data structures (Data Architecture)

- Visualization of one or more product instances

- Utilization of existing multimedia content (3D, 2D, image, and text content)

- Definitions of user groups with different perspectives

- Contextualization of diverse master and movement data

Solution

The initial use cases focused on the in-house and field service areas, as optimizing the spare parts research process offered enormous potential.

Throughout a product's lifecycle, its status can change regularly or irregularly due to software updates, modifications, functional enhancements, and spare parts. For all these events, it's crucial to build upon a solid data foundation and then define a suitable visualization structure to implement requirements as precisely as possible.

eoda helped us provide a flexible platform for visualizing the Digital Twin – the Digital Machine File (DMA). eoda not only supported us with the provision, installation, and operation of the platform, but a TRUMPF-specific platform for visualizing a Digital Twin was created.

Numerous special implementations were carried out:

- Integration of new visualization objects

- Integration of third-party software components

- Integration of existing interfaces

Handling large amounts of data allowed us to visualize diverse data in a format that users hadn't encountered in any of the existing process-leading systems. Static and dynamic data could be combined depending on the context, and additional data could be selectively brought into context as needed.

The use cases were implemented, and the potential was realized even in the first project phase. Users were quickly convinced, and the worldwide rollout of the Digital Machine File began during this initial phase.

Digital Machine File & Condition Monitoring Portal

A Central Platform for Data-Driven Business Processes at TRUMPF

TRUMPF also relies on eoda for predictive maintenance to increase data-centricity and resolve machine issues before they actually occur.

Result

ith eoda as our implementation partner, we were able to launch the Digital Machine File, efficiently handling and contextualizing large volumes of data on the platform developed by eoda. The platform also offers the necessary flexibility to harmoniously combine and visualize all content in the form of data and multimedia.

Today, the Digital Machine File visualizes over 150,000 TRUMPF products, bringing diverse data objects from various systems at different times into context and presenting the results in a user-friendly manner. Context-specifically, the Digital Machine File connects all relevant data, enabling intuitive and efficient use of information throughout the entire process chain.

Today, with over 1,700 users worldwide across the TRUMPF Group, the Digital Machine File is a central building block in our solution landscape. It serves as a Single Point of Truth and supplies surrounding systems with individual product and status data. This benefits not only service but also sales, for example, who can make their processes more efficient and customer outreach more targeted based on the bundled information within the Digital Machine File regarding installed machines and their extensions.

Furthermore, the Digital Machine File is the optimal foundation for simulating virtual production lines and conducting further data analyses—for example, for creating new digital services.

Author

Ernö Halas

IT Project Manager Digital Machine File | TRUMPF SE + Co. KG

Get started now:

We look forward to exchanging ideas with you.

Your expert on Data-Science-Projects:

Lutz Mastmayer

projects@eoda.de

Tel. +49 561 87948-370