Goal

Development and implementation of optimized operating strategies for cross-sector supply systems.

Solution

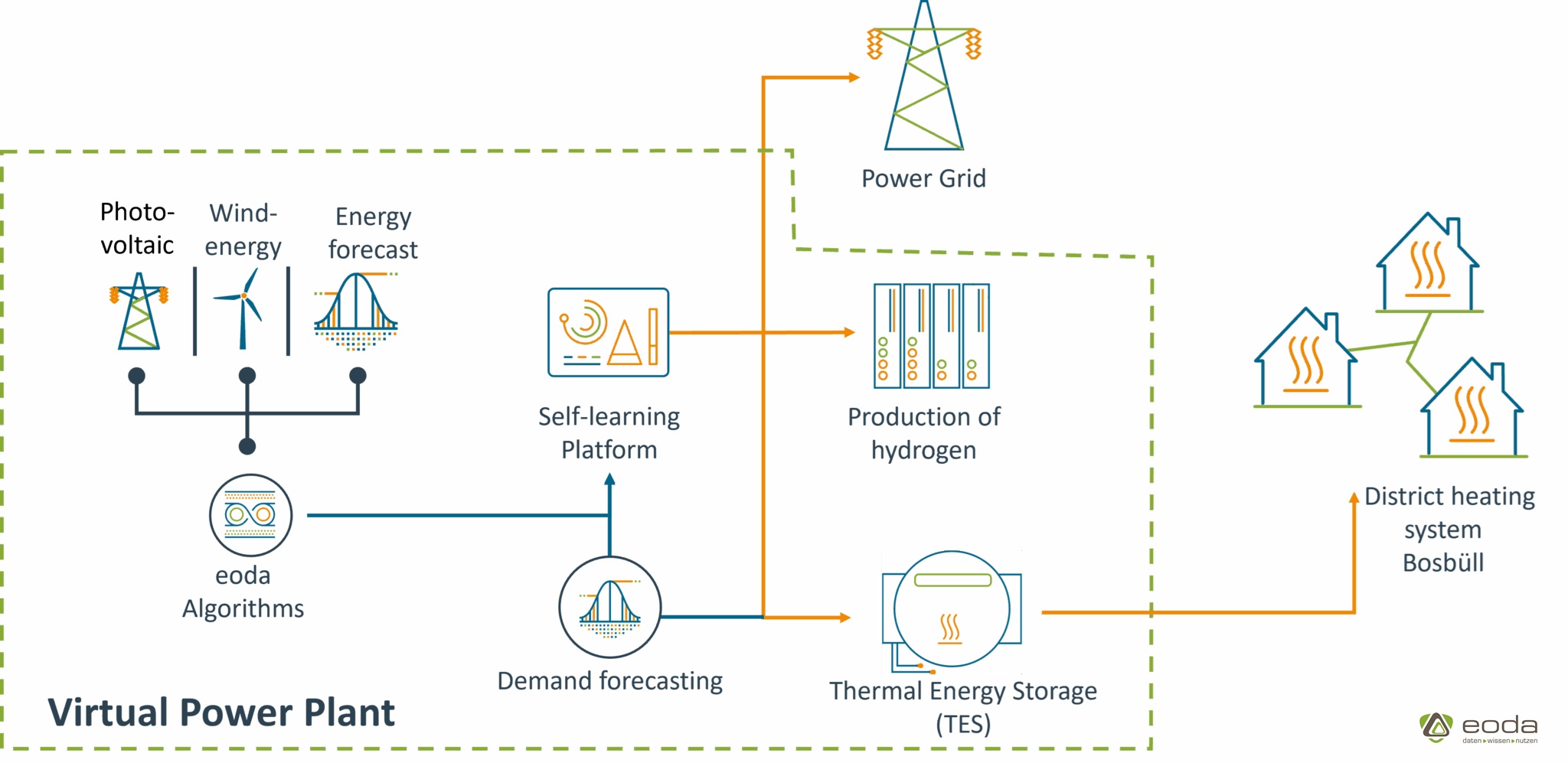

Development of predictive operating strategies using load forecasts and AI as part of the “Optinetz Bosbüll” research project.

Result

Ultimately, the predictive operating strategies in combination with AI are expected to increase the self-utilization of the electricity generated and the degree of utilization of hydrogen production by up to 20%.

Initial situation

Green and sustainable energy - an important topic of our time. The northern German municipality of Bosbüll has been showing how this can be possible for several years. The town operates two wind turbines subsidized by the Renewable Energy Sources Act (EEG), each with an output of 2 MW, and several photovoltaic systems that generate a maximum output of 170 kW. A gas boiler with an output of up to 500 kW is also located in the town's heating network to secure the supply during peak loads. However, subsidies for wind power and photovoltaic systems will expire at the end of 2029. The municipality is therefore looking for further concepts to operate the existing grid economically.

The joint project “Optinetz Bosbüll”, funded by the Federal Ministry for Economic Affairs and Climate Protection, was created with this aim in mind. In addition to VIVAVIS AG and eoda, several companies and sponsors are involved in the joint project: Fraunhofer Institute for Energy Economics and Energy System Technology IEE, GP JOULE Think GmbH & Co. KG, ARGE Netz GmbH & Co. KG and YADOS GmbH.

Goal

In order to operate the existing wind power and photovoltaic systems economically and ecologically in the future, the focus of the joint project is on the development and implementation of optimized operating strategies for the cross-sector supply system in Bosbüll. With the help of simulation-supported and forecast-based control systems and taking into account technical, economic and regulatory aspects, predictive operational management is to be realized.

Supported by intelligent and learning software, the system should independently compare demand and generation forecasts and optimize the system according to selected control variables (emissions, economic, etc.) and operate it as independently as possible. The solutions developed should be so flexible that they can respond well to dynamic developments and events.

Solution

Initially, all relevant information, aspects, criteria and technologies were bundled in the project and an all-encompassing database was generated. In the further course of the project, various software solutions were created with regard to systemic simulations and forecasts in order to provide the data sets (weather forecasts, hydraulic situations, demand and consumption analyses, etc.) live and up-to-date for the predictive, operational software. Based on historical data series and the transfer of the supply system into a virtual environment, the software solutions created can be validated live or trained independently of the real situation. This ensures the fastest possible testing and implementation and significantly minimizes the risk of incorrect decisions by the operational management.

A key step consists of integrating the energy producers and consumers via interfaces into a software platform developed by VIVAVIS specifically for the project. The different data is structured in this platform in order to avoid redundancies, anomalies and inconsistencies. This data is then made available to the system partners. On this basis, eoda develops intelligent algorithms to create AI-based evaluations and (demand) forecasts. At the same time, eoda has developed models for operational management that monitor the performance and efficiency of the system as part of quality assurance. The algorithms developed are designed for flexibility in order to be able to react individually to dynamic developments and events.

An overview of eoda's service modules in this forward-looking project:

- Generation of load forecasts for electricity and heat generation using existing measurement data

- Creation of load forecasts for electricity and heat generation and validation of the forecasting models

- Validation of the developed forecasting models and structured comparison with existing market solutions through backcasting

- Derivation of operating parameters for optimization as a basis for the development of predictive control for grid relief development of predictive control for grid relief

- Development of predictive operating strategies using load forecasting and AI in the simulation environment (predictions of user behaviour and weather forecasts)

- Mapping the operating strategies of the heating grid in Bosbüll as a reference variant based on technical data and the thermal-hydraulic simulation model

- Analysis of generation and demand time series with different scenarios and identification of potential for sector coupling

- Development of the charging strategy in the form of a schedule for all generators for the next 48 hours

- Derivation of technical and economic requirements for sector coupling

- Identification of technical and economic requirements for operating strategies

- Consideration of flexibility potential through options for intermediate storage of energy in different sectors

- Derivation of measurement and monitoring concepts

- Definition of requirements for the continuous recording of energy flows and requirements for operational energy management

- Development of a monitoring concept for continuous system monitoring and control (IoT, real-time capability, data storage,...)

- Derivation of KPIs for monitoring the overall system

- Creation of coupling possibilities between optimization of operational management of the heating network with market-oriented use of the systems

- Comparison of AI-based predictive operating strategies with canonical schedule optimization

Result

With this joint project, existing sector-coupled supply systems can be transferred to simulation environments. Using the algorithms developed by eoda, the system can compare demand and generation forecasts and optimize itself based on the defined key variables, such as emission values, economic efficiency and degree of self-sufficiency.

Ultimately, the predictive operating control in combination with AI should increase the self-consumption of the electricity generated and the degree of utilization of hydrogen production by up to 20%. The forced curtailment of wind turbines at peak times could also be reduced by almost 20%. At the same time, emissions and CO2 equivalents are reduced by up to a tenth.

The chosen procedure should be a blueprint for supply systems in Germany due to its good reproducibility.

Get started now:

We look forward to exchanging ideas with you.

Your expert on Data-Science-Projects:

Manfred Menze

projects@eoda.de

Tel. +49 561 87948-370