Advantage

Creation of new customer services based on data-based component maintenance and the associated increase in machine availability.

Data

Already existing and unclassified data from the EF3 rotary table control.

Methods

Anomaly detection: Use of cluster/density-based methods to identify OK and NOK states in the data.

Challenge

As a global system partner for factory automation, the WEISS Group, with 17 locations and approximately 500 employees, designs automation solutions for the key industries of automotive, mechanical and plant engineering, life sciences, and electronics. Key elements of WEISS's portfolio are its leading rotary indexing and heavy-duty tables for the efficient transport, movement, and positioning of components in the production and assembly process.

The rotary tables are therefore responsible for transport and are usually installed at the lowest level of the machines. This makes them a particularly critical machine component, whose maintenance, due to their location, is associated with significant effort and machine downtime.

Goal

WEISS rotary indexing and heavy-duty tables have stood for reliability and quality for decades. To further enhance these attributes, WEISS aims to obtain reliable information about the machine's condition and anticipate malfunctions using predictive maintenance. This will further increase the reliability of the rotary tables for customers and ensure the most maintenance-free operation possible.

Solution

To achieve this vision, WEISS has defined three milestones:

- Condition Monitoring: Establishment of continuous condition monitoring

- Anomaly Detection: Detection of critical conditions based on transmitted data

- Predictive Maintenance: Prediction of malfunctions and proactive intervention

Together with the data science experts from eoda, WEISS defined concrete value propositions in a workshop based on various customer journeys that the IoT features to be developed should deliver:

- Service Management: Local machine monitoring allows the service manager to be proactively informed about anomalies in the system and receive automated solution suggestions.

- Plant Management: As part of the service contract, WEISS monitors the components installed at the customer's site, delivers insightful reports, and proactively initiates necessary maintenance measures.

- Data Science: Through the data interface via OPC UA, the customer's data scientists can directly access the data from WEISS components, link it with their other data, and easily integrate it into their own processes and analyses.

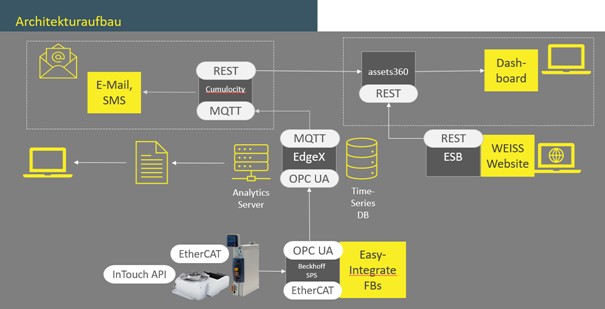

In the first development step, eoda supported WEISS in building an architecture for implementing the data solution. This architecture ranges from the OPC UA interface to sending push notifications of machine status to customers and thus provides the technical framework for the development of smart services.

eoda then managed the data and developed the analyses to detect anomalies. By using cluster/density-based methods, known OK and NOK states were identified in the data. Data patterns that do not correspond to any of the known states are marked as anomalies. The information was based on the existing, unclassified data from the EF3 rotary table controller.

To optimally display and utilize the relevant machine data and analysis results internally at WEISS, eoda also took over the development of the dashboards. The dashboards enable WEISS experts to quickly and easily record the condition of components and, if necessary, initiate maintenance directly at the customer's site. The developed dashboards are based on eoda's established data science platform, which is also used, for example, by the machine manufacturer TRUMPF as a condition monitoring portal.

Result

With the support of eoda, WEISS can generate a number of added values for both machine manufacturers and machine operators. Thanks to the Condition Monitoring and Predictive Maintenance modules, the rotary and heavy-duty tables become smart machine components that actively report changes in condition, thus further reducing the risk of long, unplanned downtimes. This creates the opportunity for WEISS to offer proactive machine monitoring as a digital service to its customers.

Consulting, project management, and software development: With eoda, WEISS received all the necessary development steps for this project from a single source. By using the proven and flexibly adaptable YUNA components, WEISS saved valuable development time and costs.

Get started now:

We look forward to exchanging ideas with you.

Your expert on Data-Science-Projects:

Lutz Mastmayer

projects@eoda.de

Tel. +49 561 87948-370