Challenge

An increasing shortage of skilled workers is making it more difficult to ensure quality, throughput and resource optimization in the complex manufacturing process for moulded parts made of particle foams.

Influencing variable

Foam pressure is the central influencing variable for controlling the manufacturing process. Measuring it is expensive, time-consuming and not possible for every molded part.

Result

Development of an AI-based assistance system for machine control based on a virtual foam pressure sensor.

Challenge

Erlenbach GmbH is an international technology leader in the manufacture of processing systems for particle foams, for example for insulation boards or packaging.

Logo Erlenbach

Packaging and other molded parts are manufactured using the steam pressure process. The machines vaporize the spherical starting material until it expands and optimally fills the desired shape.

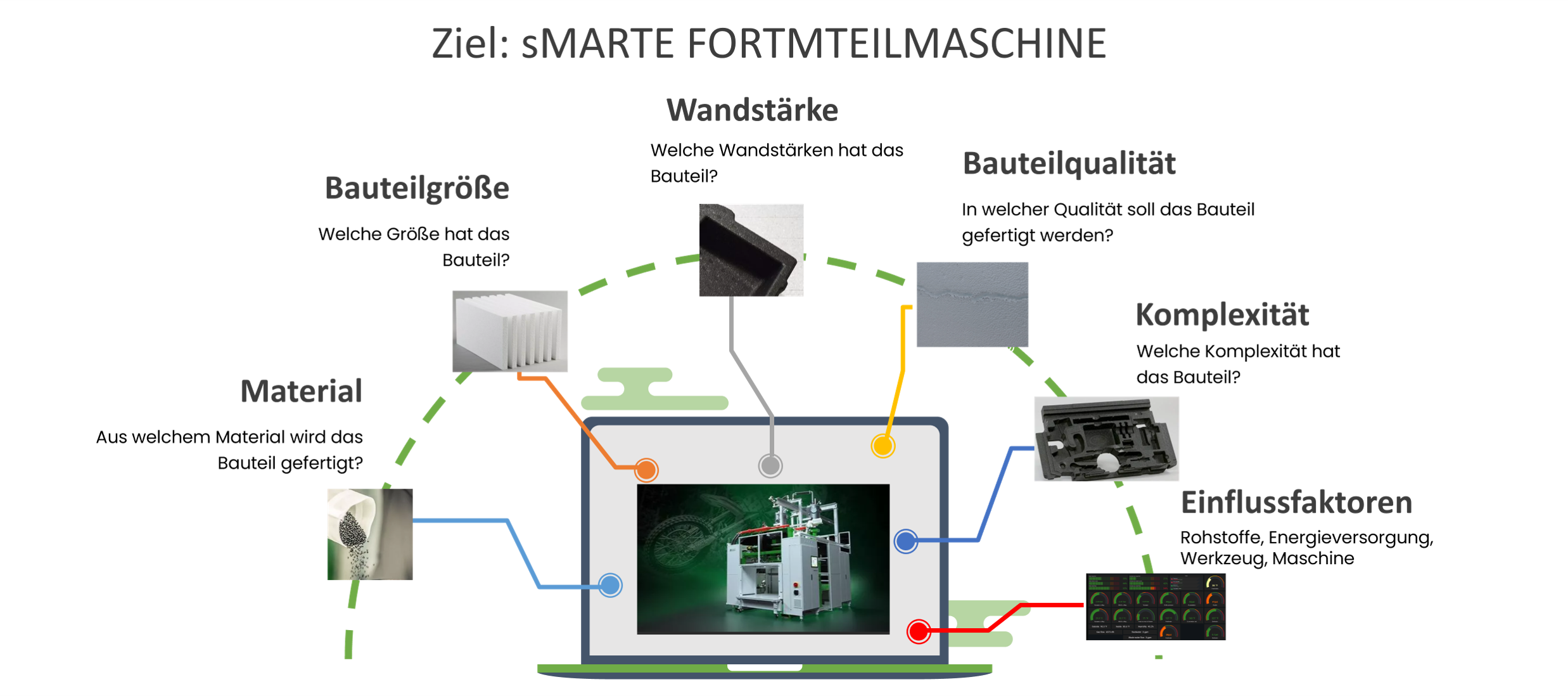

The complexity of the manufacturing process results from the large number of influencing factors and shapes to be produced with their different properties. Increasing supply difficulties also regularly make it necessary to use different materials depending on their availability. This is a major challenge for achieving consistently high output quality, on which the selected vaporization time in particular has an enormous influence.

As a rule, a longer steaming time for the material has a positive effect on the quality of the molded parts produced. In order to keep the throughput as high and the energy costs as low as possible, the optimum steaming time must be determined time and time again.

Experienced operators are able to set the Erlenbach machines in such a way that they run the machines optimally, taking into account quality requirements, throughput and energy costs. However, in times of an increasing shortage of skilled workers, these experienced experts are becoming increasingly rare.

Goal

Erlenbach wants to create a solution module for its customers that helps them to better meet these challenges: An assistance system that makes it much easier to operate Erlenbach machines - based on artificial intelligence.

Solution

Erlenbach relies on the data science experts at eoda to develop the AI-based assistance system for automated machine control.

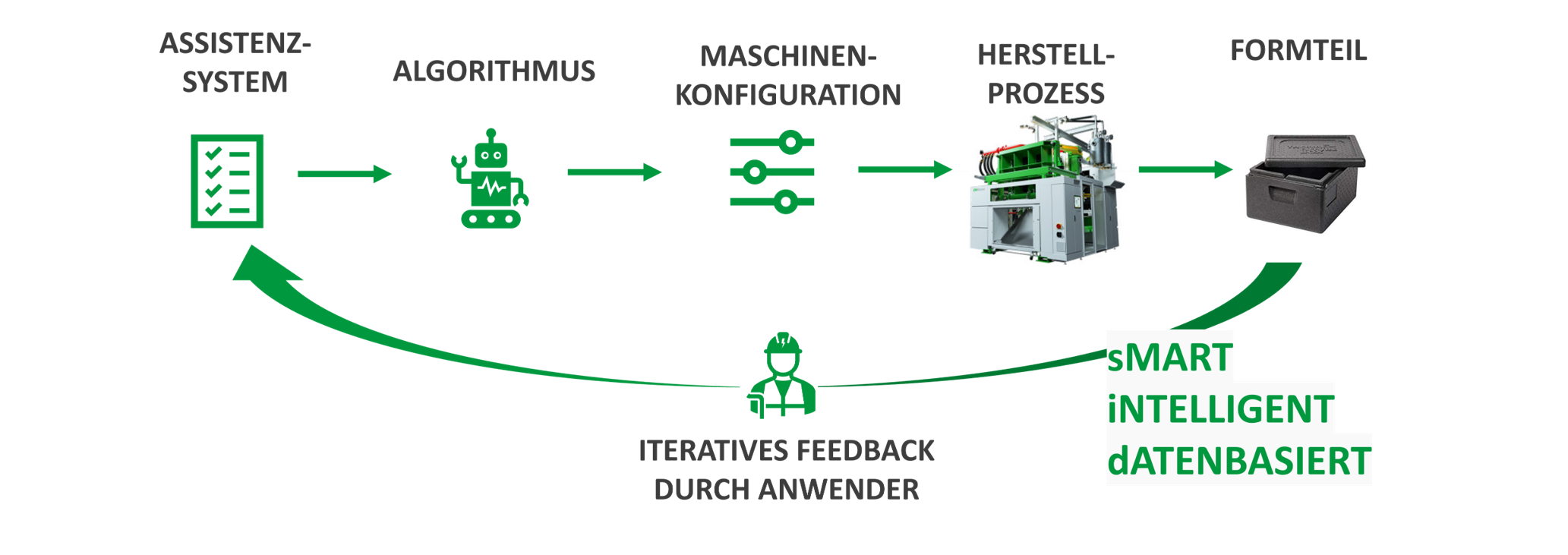

The central influencing variable for the creation of a system for automated machine control at Erlenbach is the foam pressure. The production process on the machine can be controlled very well based on the resulting foam pressure curve.

To determine this, special sensors are required, which are very costly and maintenance-intensive. In addition, the recording itself is very complex and not possible for every molded part.

In order to be able to continue with the realization of the AI-based assistance system, the data experts at eoda have created an alternative for determining the foam pressure together with Erlenbach: The virtual foam pressure sensor. This results from the combination of other existing data sources from the entire manufacturing process, such as chamber pressure or chamber temperature. By consistently optimizing the model, it was possible to determine which influences affect the foam pressure and how. After just a short time, the foam pressure could be predicted very precisely.

In addition, Erlenbach's internal test series enabled further training data to be generated in a targeted manner, making it possible to guarantee a high level of reliability in the forecasts, even with different materials and molded parts. This project is therefore also an example of many AI use cases in which “big data” is not important, but rather the availability of good and varied data in order to be able to map the different framework conditions in the training data.

The reliable virtual prediction of foam pressure is a quality indicator and the technical centerpiece for the automation of machine control and the relief of machine operators. Live Prediction can either be integrated directly into the machine control system or provided in the form of an app. Machine operators can use the app to enter information on the material and moulded parts and receive concrete information on how to optimize the production process by predicting the foam pressure curve.

In addition, the foam pressure curve makes it possible to detect anomalies and thus problems in the production process or on the machine at an early stage.

Result

Rising energy costs, a shortage of skilled workers, competitive pressure: Erlenbach is tapping into artificial intelligence as a solution component for the challenges of the present and future with automated machine control. Erlenbach is thus creating an innovative digital service for its customers that enables them to save energy and personnel costs, optimize the use of resources and at the same time maintain high production volumes and quality.

What is remarkable is that this was achieved without the need for large amounts of data on the most important influencing variable to be available at the start of the project or the need for time-consuming and cost-intensive acquisition of this data using new sensor technology. The key to this project: the development of a virtual sensor.

Methodical implementation

GAM, Random Forest, XGBoost: eoda's data scientists tested and combined a variety of different models to ensure the success of the project - especially to ensure the necessary speed of the forecasts for use in live operation.

Other project partners

Get started now:

We look forward to exchanging ideas with you.

Your expert on Data-Science-Projects:

Lutz Mastmayer

projects@eoda.de

Tel. +49 561 87948-370